- Home >

- News >

- Local News

Kayaks & community: making both better

Linda Sappington

Gary Teggeman pull stapes from thin strips of cedar.

Linda Sappington

Gary Teggeman stands with four of his handcrafted cedar kayaks. A drawing for the one on the far left will take place at Mission Valley Aquatic Center on Sunday, Feb. 26.

Linda Sappington

Linda Sappington

Linda Sappington

Linda Sappington

Nancy Teggeman rides in the kayak Gary built for her, which has to dolphin insets.

Linda Sappington

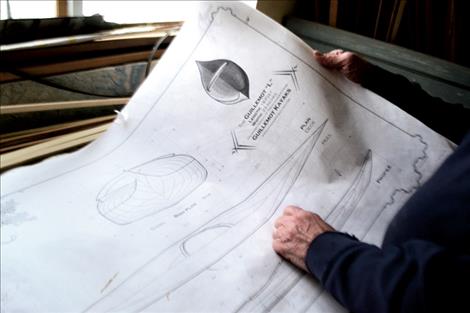

Gary Teggeman staples narrow cedar strips onto a strongback frame, above. Top right, he glances at the blueprint for his vessel created by Guillamot Kayaks. Top left, he dampens a wave inset created from contrasting cedar.

Linda Sappington

Linda Sappington

Linda Sappington

Issue Date: 2/8/2017

Last Updated: 2/7/2017 9:49:45 PM |

By

Linda Sappington

Keep Reading!

You’ve reached the limit of 3 free articles - but don’t let that stop you.